25hp Water Submersible Pump

$683≥1Piece/Pieces

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Money Gram |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Qingdao,Guangzhou |

$683≥1Piece/Pieces

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Money Gram |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Qingdao,Guangzhou |

Model No.: 25hp Submersible Pump

Brand: SLAPK

Pump Material: Cast iron/SS304/SS316/SS316L/duplex stainless steel/SS904L

Pump Diameter: 184mm; 283mm

Motor Power: 18.5kw 25hp submersible pump

Power Supply: 3 phase; 50hz or 60hz

Voltage: 380v/400v/440v/460v/480v or as per required

Outlet Diameter: 2" 3" 4" 5"

| Selling Units | : | Piece/Pieces |

| Package Type | : | 25hp water submersible pump is packed with seaworthy export standard plywood case. |

| Download | : |

|

25hp vertical multistage Submersible Water Pump outlet diameter is 2" 3" 4" 5" 6". Max flow rate is 200m3 per hour, max head meters is 175m. Cast iron material, Stainless steel 304/316/316L, duplex stainless steel or super duplex steel(2507), and SS904L.

The features of QJ Submersible Pump are as follows:

1. Submersible multi-stage pump is centrifugal or mixed flow type; water lubricated bearing is used; coupling rigid connection is used for connection with motor. The impeller of the pump is driven by the motor to generate centrifugal force, which increases the liquid energy and carries out water lifting through the diversion function of the pump shell. A check valve body is set at the upper end of the water pump to prevent the working parts from being damaged by the backflow water in the lifting pipe when the electric pump is shut down. There is a drain hole on the valve, which can slowly drain the water in the pipeline to prevent the pipeline from freezing and cracking in winter. (Note: low head submersible pump does not have check valve body)

2. The motor of deep well submersible pump is a closed water filled wet structure. Motor stator winding insulation, nylon sheath multilayer structure of electromagnetic wire. The guide bearing and thrust bearing are made of water lubricated material. The motor is filled with clean water to cool the motor and lubricate the bearing. A pressure regulating membrane is installed at the bottom of the motor to adjust the expansion and contraction pressure difference of water in the body caused by the temperature rise of the motor. The upper shaft of the motor is equipped with a sand control mechanism, which is used to prevent the mud and sand in the water from entering into the body of the deep well submersible pump.

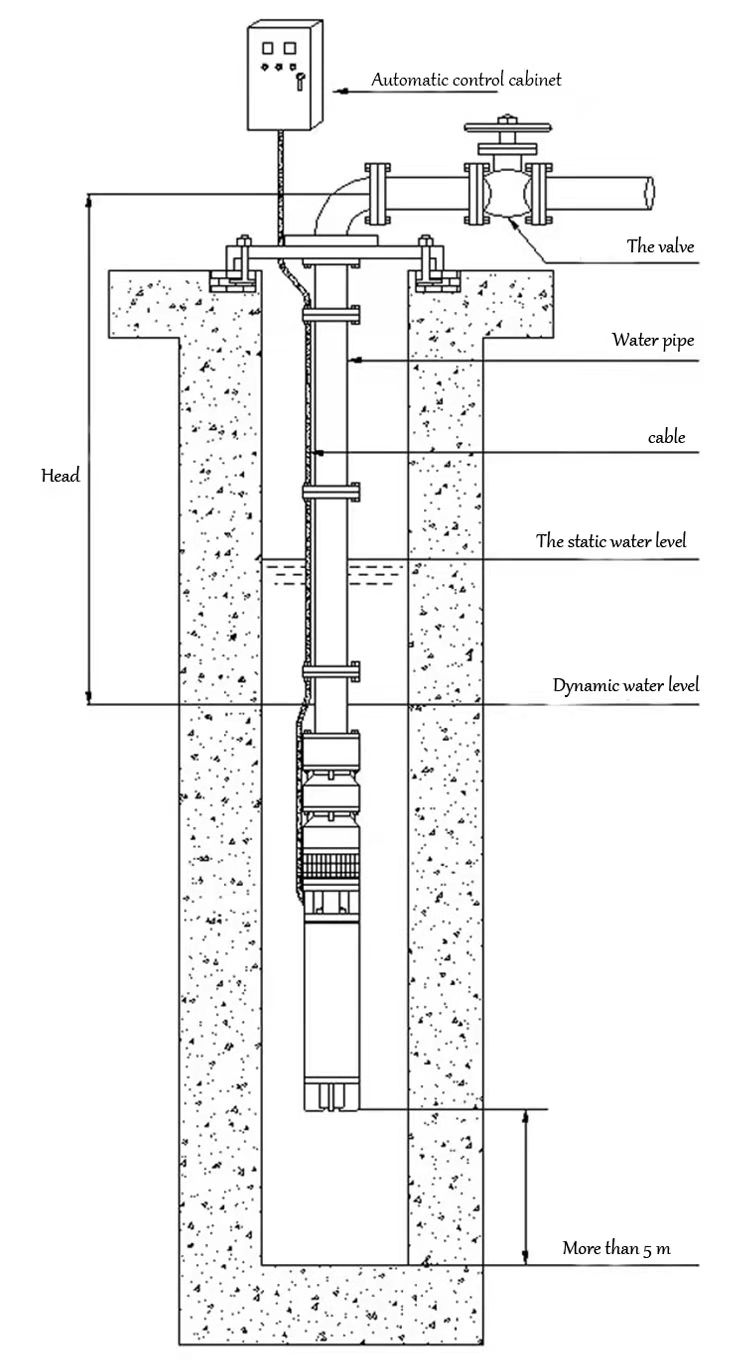

3. Pipeline part: it is used to connect the multi-stage pump, which is installed in the machine well to transport water to the ground. It is mainly composed of short water pipe, water pipe, elbow, splint and other parts of the electric pump installation parts. The short output pipe is the connecting transition part between water pipeline and multi-stage pump. The elbow is installed at the wellhead to change the direction of water flow. The splint is used to lift and fix the output pipeline in the process of chemical pump installation.

Instructions for use

1. Fill the motor with clean water before use, and tighten the water injection and air release bolt.

2. The test run on land shall not exceed one second.

3. Do not use the electric pump.

4. The motor must be fully submerged, but the depth of submergence should not be more than 70 meters.

5. Lead wire and cable joint shall be operated according to regulations (see the figure for details).

6. Order high head submersible pump (high head submersible pump type Atlas) and (high head submersible pump manual).

Conditions of use

The submersible pump can be used continuously under the following conditions:

1. Three phase AC power supply with rated frequency of 50 Hz and rated voltage of 380 ± 5% v.

2. The water level of the submersible pump is less than 70 meters, but the water level of the static water pump shall not exceed 70 meters, The water depth between the lower end of the motor and the bottom of the well is more than 1 m.

3. The water temperature shall not be higher than 20. c.

4. Water quality requirements:

(1) sand content in water shall not be greater than 0.01% (weight ratio);

(2) The pH value ranged from 6.5 to 8.5

(3) The content of chloride ion is not more than 400 mg / L. 5. It is required that the well should be positive and smooth, and there should be no staggered well pipes.

Matters needing attention:

The cable joint shall be carried out in strict accordance with the attached drawings;

1. Before going down the well, check whether the screws of each part are loose, whether the cable is broken, whether the motor is leaking, and whether the rotation of the motor shaft and water pump shaft is flexible and free of obstruction;

2. Before running into the well, check that the motor resistance should be above 150 m Ω

3. Motor water injection should be carefully prevented from false full;

4. Protection switch and starting equipment shall be equipped according to regulations;

5. When the motor is running for 2500d, a major overhaul should be carried out, and a minor overhaul should be carried out at 1500d;

6. When the electric pump is stopped for storage, the water stored in the motor shall be drained completely;

7. It is strictly forbidden to pretend that you don't understand. Disassembly and repair should be carried out in our factory or fixed repair factory;

8. Frequent "start" and "stop" are prohibited:

9. Ground test motor steering shall be carried out within one second in an instant;

10. When installing the electric pump, be careful to prevent foreign matters from falling into the well;

11. Stop the machine for maintenance in case of the following conditions:

(1) The current and voltage exceed the rated value.

(2) The flow rate decreased significantly.

(3) Water pump intermittent water or sound vibration is large.

(4) The protection switch trips frequently.

(5) The motor resistance is less than 0.5 megohm.

Water submersible pump installed diagram:

1. How to circulate head means (TDH):

To calculate Total Dynamic Head, also known as TDH, we need to calculate three things:

A) The Vertical Rise.

B) The Friction Losses of all the pipe and components the liquid encounters on the discharge of the pump.

C) After calculating both, add them together to calculate TDH.

2. Flow rate(m3/hr; GPM)

25hp submersible pump models:

(Notice: Flow rate, head meters, motor power and materials, a available 12 inch submersible pump will be chose. Inquiry, please)

Model Power Flow range Head range Outlet Diameter Pump dia QJ type kw hp m3/h m Inch(") mm 200QJ20-175/13 18.5 25 18-22 150-210 2" 184 200QJ25-154/11 18.5 25 23-27 138-184 2" 184 200QJ32-117/9 18.5 25 29-35 90-132 2" 184 200QJ40-104/8 18.5 25 37-43 89-124 2" 184 200QJ50-78/6 18.5 25 46-54 63-93 2" 184 200QJ80-55/5 18.5 25 74-86 47-63 4" 184 250QJ50-80/4 18.5 25 46-54 68-92 4" 233 250QJ63-60/3 18.5 25 58-68 51-69 4" 233 250QJ125-32/2 18.5 25 116-134 27-37 5" 233 250QJ140-30/2 18.5 25 130-150 26-34 5" 233 300QJ200-20/1 18.5 25 186-214 17-23 6" 233

Water Submersible Pump Applications:

1. Ground underground water pumping

2. Farmland agricultural irrigation system

3. Sea water, shipyard, offshore, boat ship, mariculture, floating dock, salt water

4. Drawing water from deep well or borehole

5. Pumping water from lake, river, vessel, tank, reservoir

6. Fountain projects: horizontal installed

Submersible Pump Accessories:

Control panels, submersible power cables, pipe and frequency inverter or some accessories matched submersible water pump. Inquiry, please

FAQ

Q:How long is warranty?

A:About 24 months.

Q:How long is production lead time?

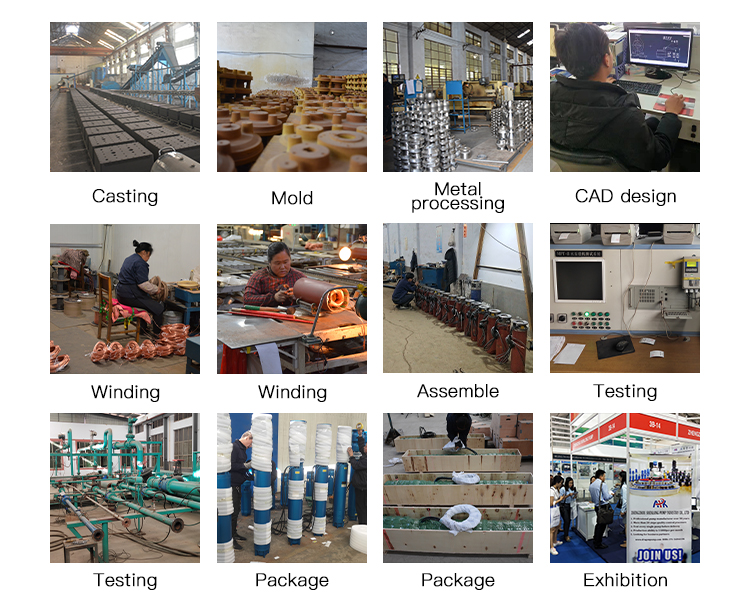

A: Normal production of water submersible pump is about 7-25 days. 85 sets of production machines which includes grinding machines, CNC, lathe, Milling, High speed punch press machine, testing machine, with sufficient spare parts stock to guarantee the production capacity of 11,000 sets per month

Q:What’s type of shipping?

A: Water submersible pump is delivered by sea freight or air freight. Or we delivered water submersible pump to your own China forwarder. EXW, FOB, CIF, DDP, all is available.

Q:How do I know pump quality?

A: Testing videos and testing reports will be shared. Or, The Third Party will be available, such as ABS.

Q:How can I pay for my items?

A:Usually by T/T, 30% , 50%, 100% down payment once PI confirmed, the balance will be paid after inspection and before shipment.

L/C at sight.

Q: We don't know which pump model we need ,can you help us ?

A: Yes, please tell me your detail requirements, include liquid, flow rate, head. Our engineers team will calculate & select most suitable pump model for you, offer pump solution for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.